We Make Implementing Vision Easy

Turnkey Vision Inspection Solutions

kmV engineers, builds and installs turnkey vision solutions to help manufacturing and packaging companies eliminate and prevent issues with manufacturing, labeling, packaging, coding and packing their products.

Our vision solutions are divided into 3 families: iSight 20/20 solutions, iSight solutions and Print and Inspect solutions.

The iSight 20/20 family of inspection systems was developed to provide our customers with a lower-cost yet robust turnkey vision solution with some of the features of a full-blown iSight solution.

- Controls for up to 4 Cameras

- Compact design = smaller footprint

- Optional +AI vision tools available

- Includes rejector and reject verify sensor

- Secure Cloud-based System Backup and Remote Service

- Doesn’t include a statistics package

Most iSight 20/20 solutions can be installed and commissioned within 72 hours.

The iSight Lightning family of PC-based inspection solutions was engineered to accommodate complex and higher-speed inspections.

- The PC-based platform features kmV designed HMI experience

- Allows for multiple inspections with higher line speeds

- Controls for up to 14 cameras

- Perfect for label inspections on round containers

- AI+ allows solution to detect label defects such as burns, bubbles, blisters, smudges & tears.

- Secure Cloud-based System Backup and Remote Service

- Statistical package included

- Upgraded controls allow for advanced product handling – side grips

Thermal Transfer Print and Inspection

- The iSight Print and Inspect inspection system was specifically engineered for the Pharmaceutical Industry to work through the unique challenges associated with thermal transfer printing.

- Features CFR21 – Part 11 Compliance.

- The iSight Print and Inspect system is a complete solution featuring a thermal transfer printer with Laptop, and a single camera inspection system with an integrated control panel, PC, backup power supply, and large touchscreen HMI

What kmV's Vision Solutions Can Do for You

kmV's own Michael H. walks us through all of the different types of inspections our turnkey iSight and iSight 20/20 Vision Solutions can perform for you.

Our team draws from a solid knowledge base to get things done right the first time, every time.

Our Proven Turnkey Vision Solutions

All of our iSight inspection systems include: a PC, touch screen monitor, cameras, lenses, lighting and mounts, a rejector and reject verification, downstream jam detection, and secure, cloud-based system backups with remote service.

Learn more about our robust iSight vision inspection systems designed for Print and Label Inspections, Empty Container Inspections, and Filled Container Inspections below.

Print and Inspect

Thermal transfer printing and vision inspection in one powerful solution for the Pharmacuetical industry.

Applied Labels

Verifies that the correct labels have been applied in the proper way on just about any container.

In-Mold Labels

Developed to address the unique issues associated with in-mold labeling - blisters, wrinkles, burn throughs.

Human Readable Codes

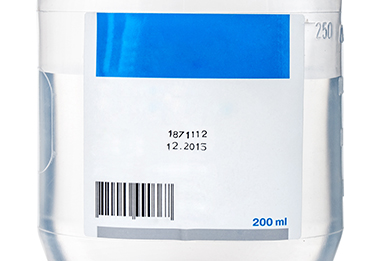

Verify ink jet, laser, and thermal transfer printed codes on any and all surfaces.

Mold Tracking

Tracks bottle mold ID's to help protect against small issues becoming big problems.

1D & 2D Code Verification

Verifies correct 1D & 2D codes are present; verifies proper match codes.

Neck & Sealing Surface

Inspects the neck profile and sealing surface of your empty plastic bottles, tubs, and jars to ensure proper seal.

Neck and Sidewall

Verifies that the neck and sidewalls of your HDPE and PET bottles are properly formed and free from contamination.

Gate and Bottomwall

Verifies that the gate is well formed & in its proper place; detects contamination on the bottom wall of the container.

Flap and Seal Integrity

Ensures that case flaps are present and in the proper position; can also verify case is sealed properly.

Kit Integrity

Verifies that all items that are supposed to be in a kit are present, properly oriented and in the correct position.

Proper Product

Verifies that the proper products have been correctly placed into a case or carton before the box is sealed.