iSight Bottle Neck Inspector

Plastic containers are constantly changing as brands battle for the attention on crowded retail shelves. Container size, shape and color for a certain brand can change pretty frequently. kmV’s isight family of vision inspection systems are designed to easily adapt to these changes while keeping the user experience as simple as possible.

iSight for Bottle Necks utilizes 1-4 cameras to do a complete inspection of the neck and sealing surface of your empty plastic bottles, pails and jars. kmV’s proprietary Power Tools vision suite simplifies adding new recipes while available automated camera positioning and a comprehesive recipe library make running mulitple products a snap.

It’s modular design allows for easy expansion as your inspection needs change and grow – ensuring that your investment will continue to save you money for years to come. Though most applications wont require it, the iSight for Bottle Necks can also be fitted with special lensing to ensure your bottles pass the most stringent specifications.

iSight Reports allow you to fully understand the yields, trends and statistics of the inspected product to help control your manufacturing process.

Of course every system is turnkey, including pre-job lab work up, design, build, FAT, installation, SAT, user and administrator training and available 24/7 service. Remote service is included with every system to minimze your downtme.

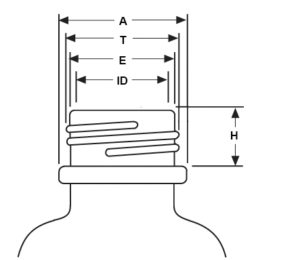

Neck Measurements

Proper dimensions and finish = safe product

Properly sealed bottles keep product fresh and free from contaminates. Confirming proper dimensions of the neck is the safest way to ensure a proper seal. For 95% of bottling applications, checking the Height (H), the thread width (T) and the exterior width of the neck opening (E) is enough to ensure proper seal. Adding additional cameras and/or specialized lenses will allow for more and precise measurements.