iSight Cap Inspector

Robust Turnkey Cap Inspections

iSight for Caps utilizes 1- 4 cameras to inspect filled bottles for proper cap color, placement and position. The robustness of the system makes inspection spraying, spouted and pull caps a breeze. Integrated process controls can be used to start or stop upstream and downstream equipment and remote service is included with every system to minimize your down time.

Inspections performed include:

- Cap Presence

- Cap Position & Placement

- Cap Color

- Tamper Band Integrity

- Safety Seal Integrity

- Trigger Cap Assembly

Focus Industries

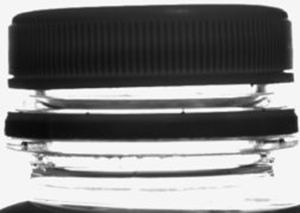

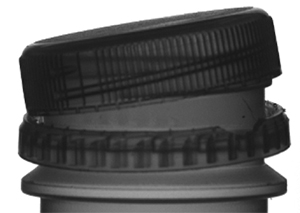

Examples of Cap Inspections

Ensuring the correct cap is securely seated on the bottle is extremely important to both your brand and your customers. A properly seated cap keeps products fresh and contaminate free while keeping the packaging neat and clean. Colorized caps are used for branding and to inform customers of the flavor, variety or type of product in the bottle. These are just a few of the label inspections that the iSight Cap Inspector has been deployed to perform.

Power Tools for Color Caps

We've created a whole new way to train cameras to see the true color of a bottle cap.

Green isn’t always green – sometimes it’s lime, sometimes it’s cucumber, mint or apple. Shades of colors communicate a lot about your product to customers. kmV’s Power Tool for Color Caps helps ensure the proper color cap is placed on every bottle filled. We can tell the difference between lime and apple.

Power Tool for Color Caps offers self-training capabilities for our iSight for Caps. The inspection system learns the color it’s supposed to look for simply by watch bottles go by. One hundred bottles or less is all it takes.

The same color cap can vary in tone from batch to batch – confusing standard color vision tools and resulting in a lot of false rejects. Power Tools for Color Caps offers additional capabilities to account for slight varitions in color, tone and hue – reducing downtime and wasted product.

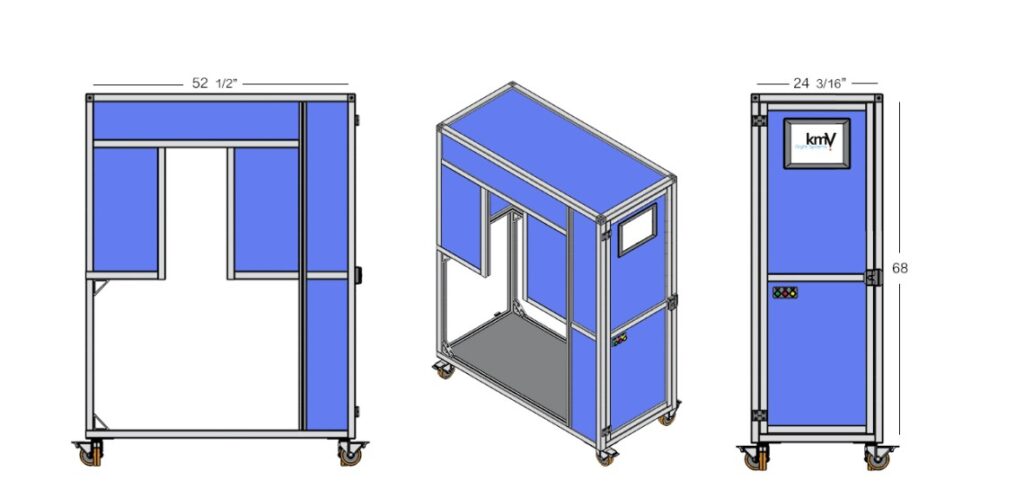

Enclosure Specifications

The standard iSight 20/20 Label Inspector and Label Inspector+ enclosure features a 24 3/16`` x 52 1/2`` footprint - one of smallest ever and yet it has all of the features kmV's systems are known for: Quick install, Integrated Control Panel and HMI, Rejector and Reject Verification, Administrative Controls (password protected), kmV's Secured, Cloud-Based System Backup, Built-in Remote Access for remote service and Integrated Process Control Signals.

System Specifications

| Feature | iSight Cap Inspector |

|---|---|

| Camera Resolution/Optics | B/W Standard Resolution - Standard, Color Optional |

| Number of Camera | 1-4 Cameras |

| Cap Types | Plain, Child-Resistant, Continuous Thread, Dropper, Flip, Sprayer, Yorker |

| Cap Materials | Colored and Natural HDPE, Metal |

| Attributes Detected | Color, Tamper Band, Safety Seal, Placement & Integrity |

| Interface | 12" Touch Screen |

| Product Tracking | Time-Based (Encoder Optional) |

| Rejector Type | Mechanical Rejector w/ Reject Verify included |

| Production Counts with Yield Tracking | |

| Stack Light Notification | |

| Downstream Jam Alert | |

| Recipe Management | |

| Cloud-based Backups | |

| Remote Support |