iSight 20/20 Code Reader

Capable & Affordable Code Verification

The iSight 20/20 Code Reader inspection system typically utilizes 1 camera to reliably verify 1D, 2D and ink jet printed codes on any and all surfaces. Our Smart AI+ technology allows you to complete inspections never before possible with standard rules-based vision tools. Smart AI+ tools are robust enough to reliably read codes distorted by varying line speeds, curved surfaces, uneven surfaces and packaging textures.

- Bar Codes

- 2D Codes

- Human Readable Codes

- Laser Printed

- Inkjet Printed

- Laser Etched

Focus Industries

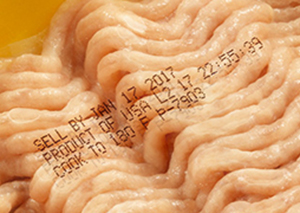

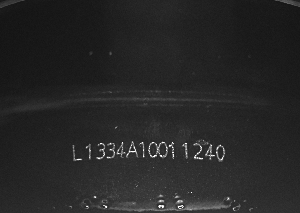

Examples of Code Verification

These are just a few of the types of Code Verification that the iSight 20/20 Code Reader has been deployed to perform.

Curved Surfaces

Eggs, Candy, Tablets Capsules

Flat Pack

Frozen Food, Boxed Dry Goods

Grooved Surfaces

Textured or Rough Surfaces

Uneven Surfaces

Can Lids, sides and bottoms

Print on Bends

Milk Jugs, Sqround containers

Mold Cavity ID

Blow Molded Bottles

Low Contrast

Glass, Metal, Plastic

Should You Consider + Smart AI?

Our +Smart AI vision tools offer a lot of benefits over today's standard vision tools - especially when it comes to verifying codes printed on a running packaging line.

iSight 20/20 Code Reader +Smart AI Print Inspection

+Smart AI makes inspecting human-readable codes reliable and easy on any type of product.

Like your best operator on their best day - every day!

Like your best operator on their best day - every day!

Learn more about the Benefits of Smart AI

Follow the link to learn more about kmV's Smart AI tools and how they can help you improve your process

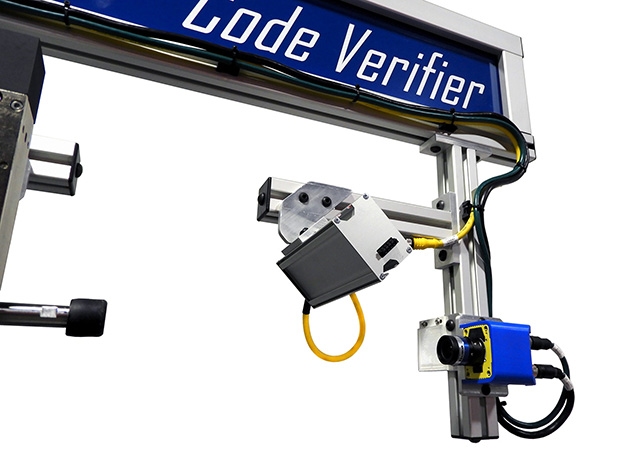

System Overview

The iSight 20/20 Code Reader and Code Reader+ features a 20`` x 33.5`` footprint - our smallest ever and has all of the features kmV's systems are known for: Easy to Install (usually within 2 hours), Integrated Control Panel and HMI, Rejector and Reject Verification, Administrative Controls (password protected), kmV's Secured, Cloud-Based System Backup, Built-in Remote Access for remote service and Integrated Process Control Signals.

Ships Ready to Go

Thanks to all the work done in our vision lab and on the assembly floor, this compact vision system arrives at your facility ready for action. Roll it in, clamp it down, and start inspecting.

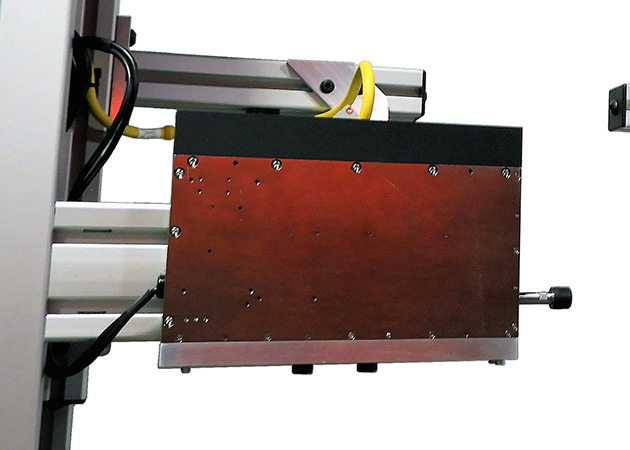

Cameras and Lights matched to your needs

Our team spends time with samples of your products in our vision label to carefully select the camera, lensing and lighting required to meet your inspection requirements.

Total Control at Your Fingertips

The industrial touchscreen allows access to vision system software, view live inspection streams, adjust vision tools, view live and previous run logs.

Rejector Ensures no Bad Product Gets Through

Each iSight 20/20 inspection system comes complete with a rejector and reject verify sensor. The type of rejector used is dependent on product type.

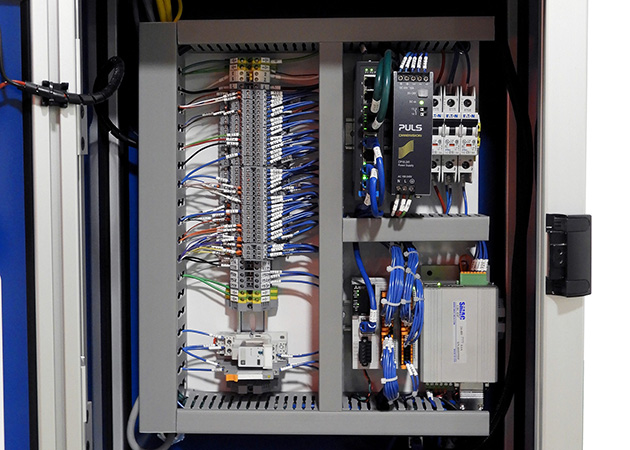

Easy Access Control panel

The iSight20/20 system control panel is out of the way but easy to get to when access is required.

System Specifications

| Feature | iSight 20/20 Code Reader + | |

|---|---|---|

| Camera Resolution/Optics | Standard Resolution | High Resolution with AI Technology |

| Camera Position | Factory Preset (Adjustable Optional) | Adjustable |

| Vision Tools | Standard Vision Tools | + Smart AI Tools |

| Codes Verified | 2D and Barcode | 2D, Barcode & Human Readable Codes |

| Vision Interface | 12" Touch Screen | 12" Touch Screen |

| Product Tracking | Time-Based | Time-Based (Encoder Optional) |

| Production Counts with Yield Tracking | ||

| Stack Light Notification | ||

| Mechanical Rejector with Reject Verify | ||

| Downstream Jam Alert | ||

| Recipe Management | ||

| Cloud-based Backups | ||

| Remote Support |

Interested? Let's get in touch!

If you've got a project that you're working on or have questions about the iSight 20/20 Label Inspector, contact us today!